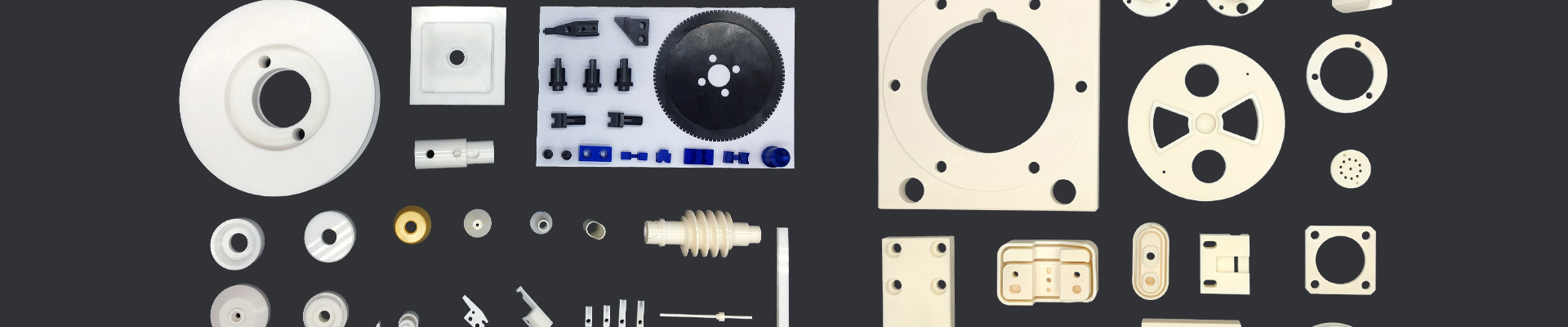

Founded in June 2006, the company is specialized in the R&D, manufacturing and sales of non-standard industrial ceramics, hard alloys (tungsten steel), various metal and non-metal precision mechanical parts.

After more than ten years of development, it has accumulated rich industry experience and trained a group of professional technicians. It has a complete production process and quality management system, as well as a complete set of precision processing equipment and testing equipment. At present, it has more than 1,000 domestic and foreign customers, and has cooperated with more than 30 universities and research institutes. It has a high reputation and good reputation in the same industry. The company‘s overall strength is in the leading position in the industry.

Main Products:

The company specializes in the production of zirconia ceramic precision parts,alumina ceramic precision parts,silicon nitride ceramicprecision parts,silicon carbide ceramicprecision parts,machinable ceramicprecision parts,microporous ceramicprecision parts,aluminum nitride ceramicprecision parts, Cemented carbide(tungsten steel) precision parts, etc.

Products are widely used in precision machinery manufacturing, microelectronics, semiconductor, aerospace, biomedical, fiber optic communications, testing and inspection, solar photovoltaic and other fields.

Material Properties:

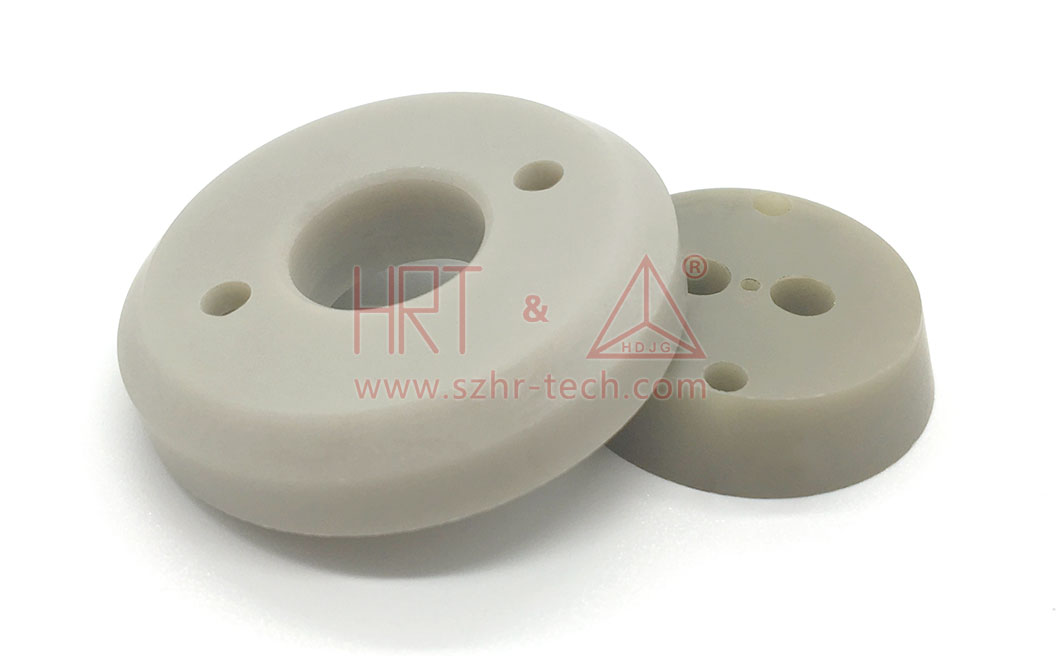

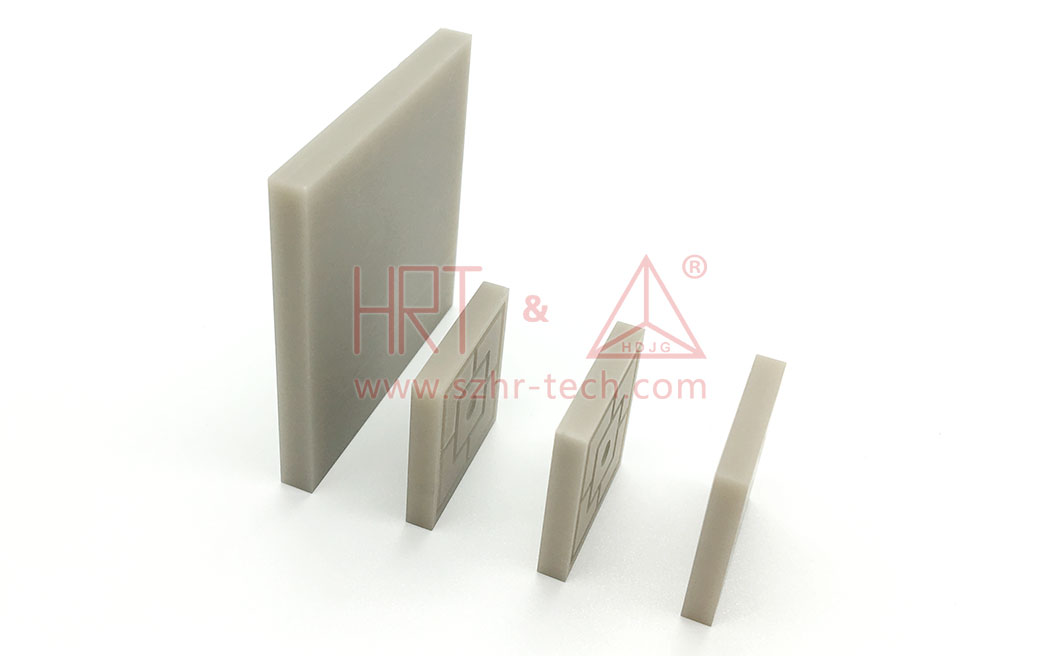

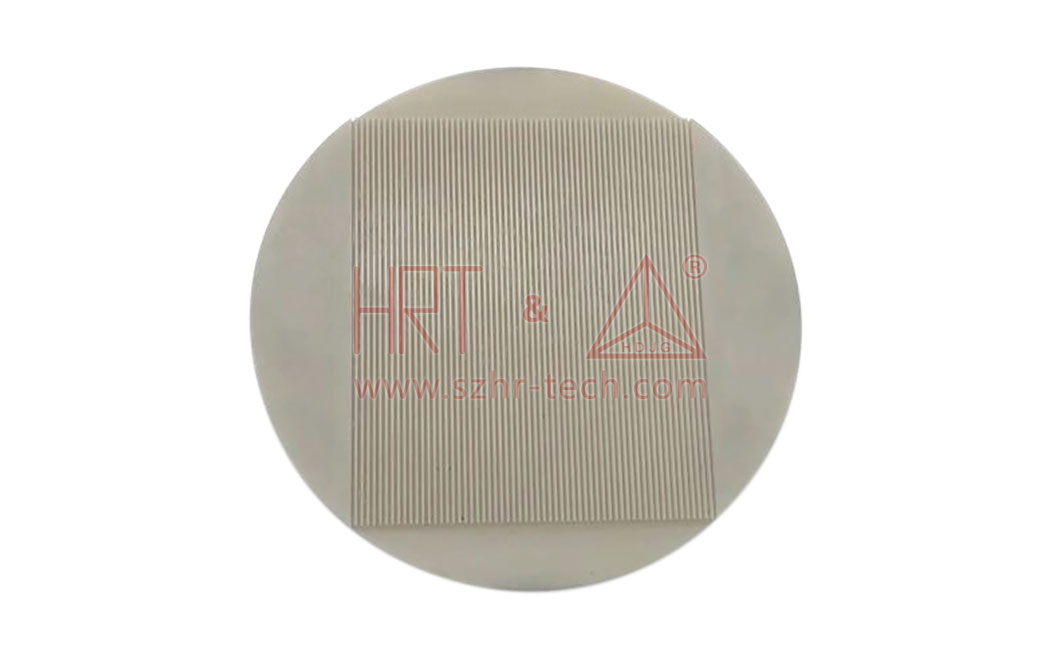

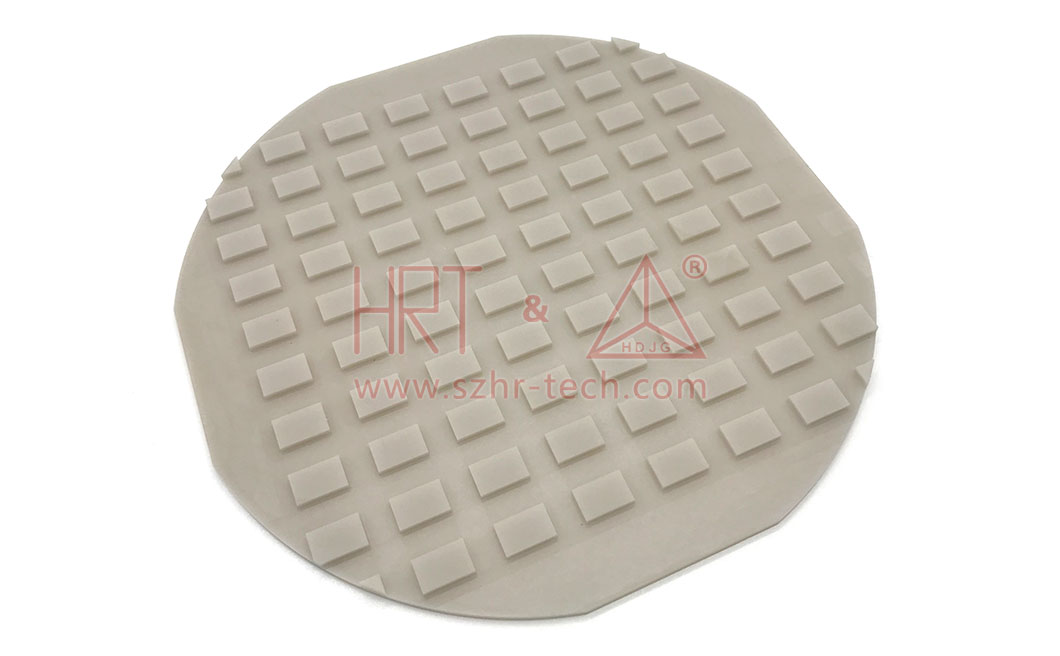

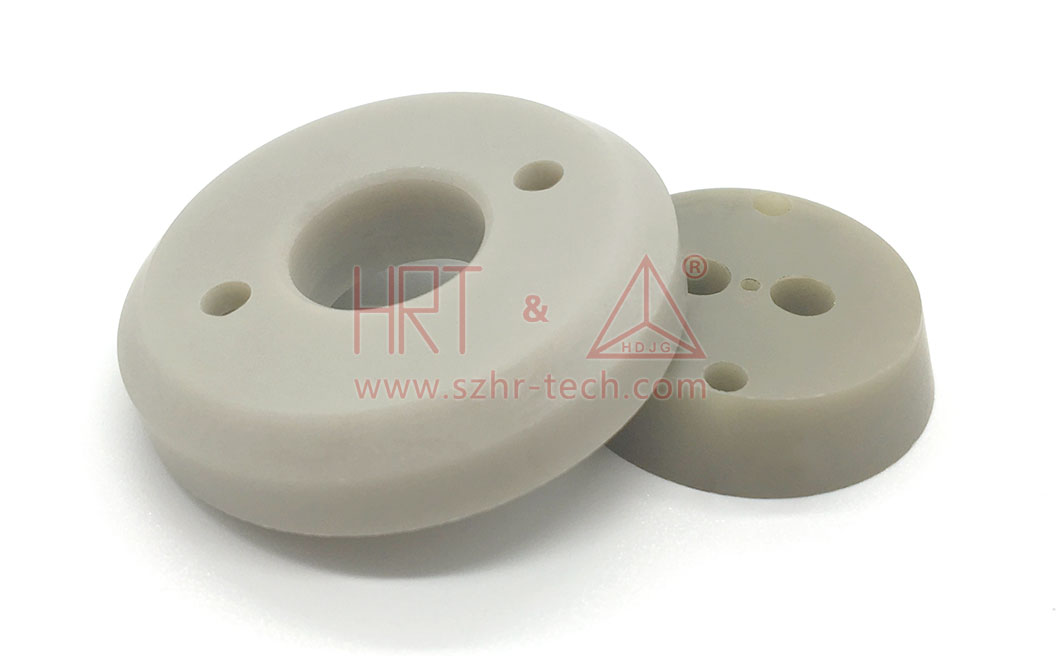

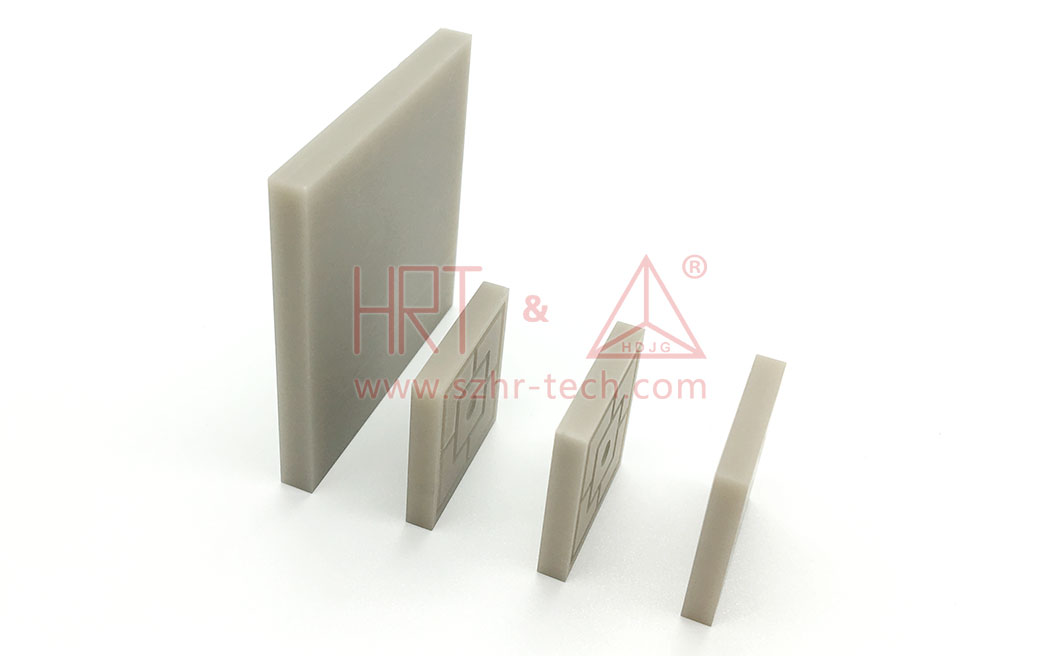

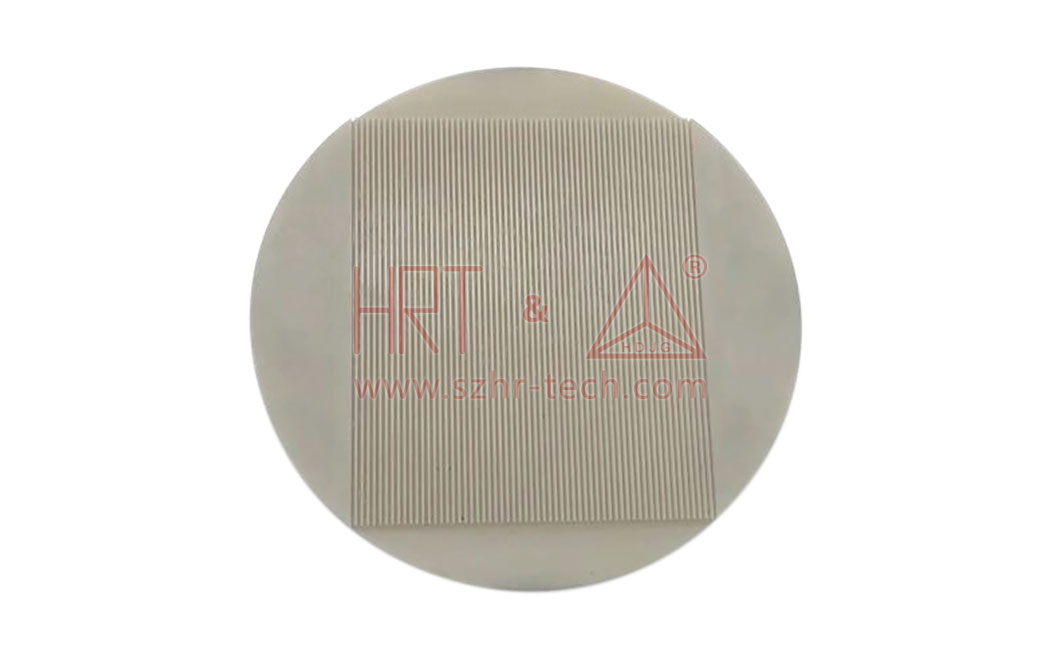

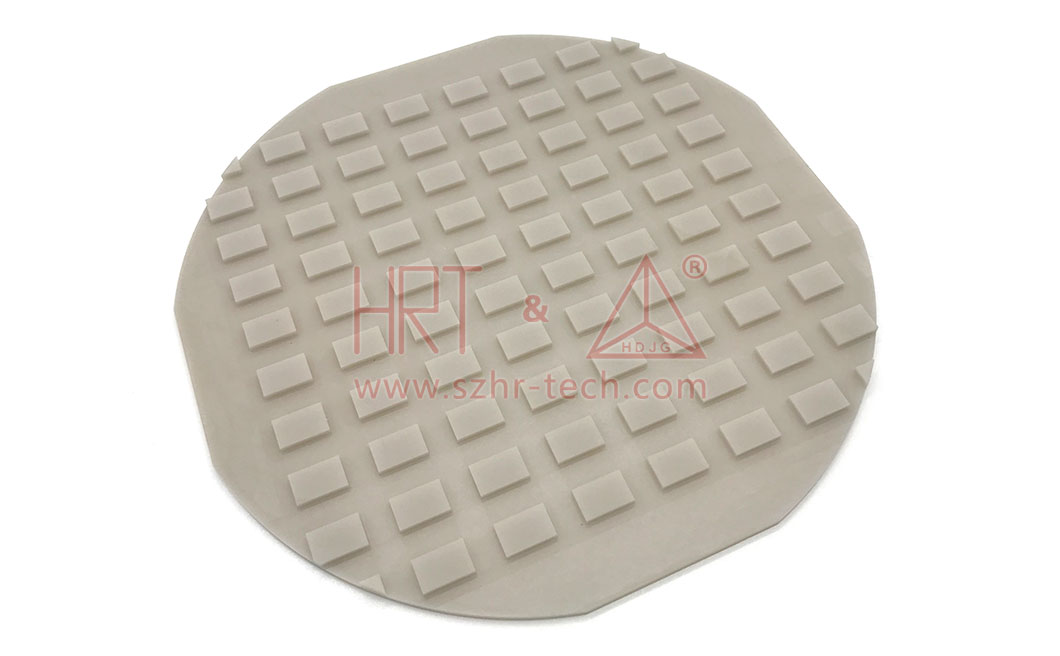

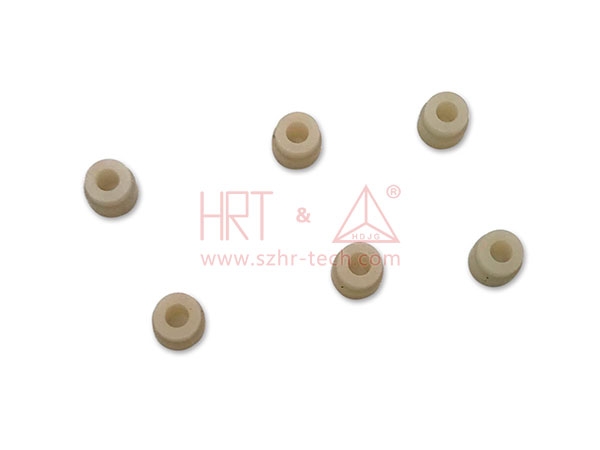

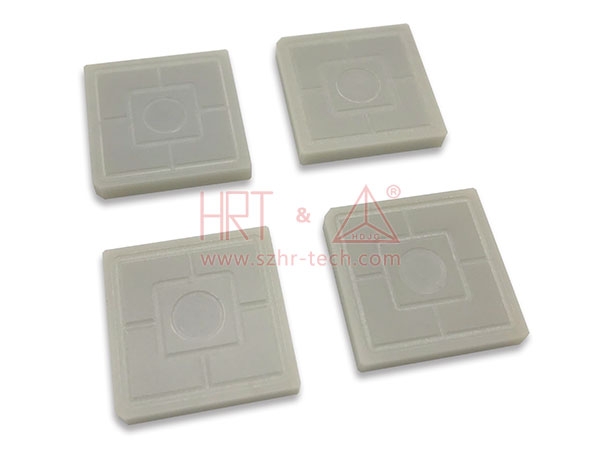

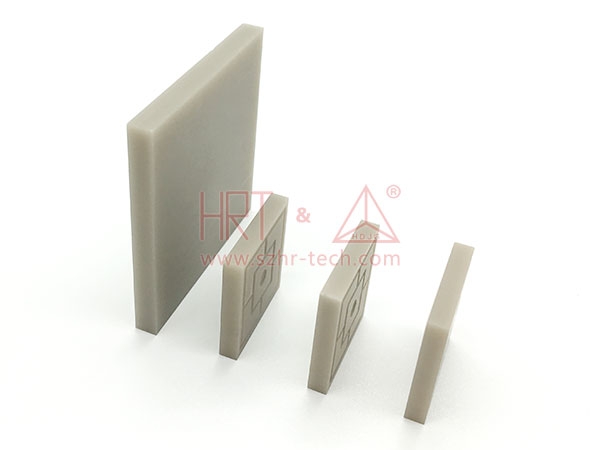

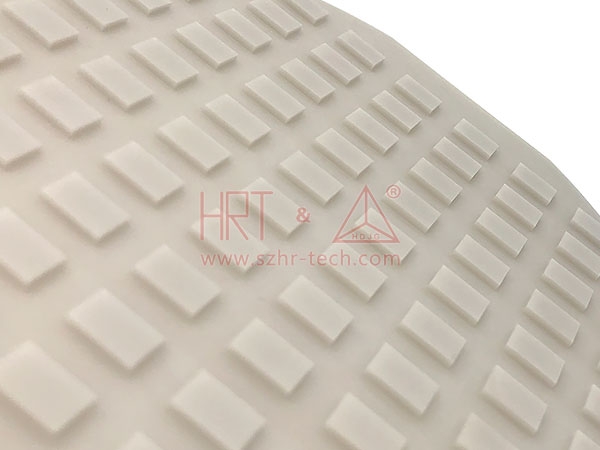

Sample Display:

Ordering Instructions:

Provide as much part information as possible (drawings or samples, usage environment, etc.) and your requirements (quantity, delivery date, etc.).We will recommend product solutions and quotations to meet your requirements.

Contact Details:

TEL:18025468212 / 0755-26793059,

WeChat:18025468212

Q Q:2311257469

E-mail:HaoRuiGongYe@126.com

Thank you for your browsing, we are confident that we can fulfill your product requirements well and look forward to be your reliable partner!

Browse more products, please click

Material Properties:

| 95% Alumina | 99% Alumina | Zirconia | Silicon carbide | Silicon nitride | Aluminum nitride | Machinable ceramic | |

|

Colour |

white | Light yellow | white | black | black | gray | white |

| Density (g/cm3) | 3.7g/cm3 | 3.9g/cm3 | 6.02g/cm3 | 3.2g/cm3 | 3.25g/cm3 | 3.2g/cm3 | 2.48g/cm3 |

|

Water Absorption |

0 % | 0 % | 0 % | 0 % | 0 % | 0 % | 0 % |

| Hardness(HV) | 23.7 | 23.7 | 16.5 | 33 | 20 | - | - |

| Flexural Strength(MPa) | 300MPa | 400MPa | 1100MPa | 450MPa | 800MPa | 310MPa | 91MPa |

| Compressive Strength(MPa) | 2500MPa | 2800MPa | 3600MPa | 2000MPa | 2600MPa | - | 340MPa |

| Young‘s Modulus Of Elasticity | 300GPa | 300GPa | 320GPa | 450GPa | 290GPa | 310~350GPa | 65GPa |

| Poisson‘s Ratio | 0.23 | 0.23 | 0.25 | 0.14 | 0.24 | 0.24 | 0.29 |

| Thermal Conductivity | 20W/m°C | 32W/m°C | 3W/m°C | 50W/m°C | 25W/m°C | 150W/m°C |

1.46W/m°C

|

|

Dielectric Strength |

14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm |

| Volume Resistivity(25℃) | >1014Ω·cm | >1014Ω·cm | >1014Ω·cm | >105Ω·cm | >1014Ω·cm | >1014Ω·cm | >1014Ω·cm |

This data is typical for laboratory testing and the actual characteristics of a particular production batch may vary.

Machining Accuracy(1) Axis: roundness 0.002 mm, concentricity 0.002 mm, smoothness Ra0.1;

(2) Hole: the minimum processing hole diameter is 0.2 mm and the depth is up to 6 mm (depending on the material);

(3) Slot (seam): a minimum of 0.1 mm narrow groove, and grooves of various shapes;

(4) Plane: 0.1MM sheet with minimum processable thickness, parallelism 0.001mm, measurement tolerance 0.001 mm, finish Ra0.1;

(5) Thread: The minimum Machinable M2 internal thread, the accuracy of GB-7h, the external thread size is not limited, the accuracy is GB-6g.

Sample Display:

Ordering Instructions:

Provide as much part information as possible (drawings or samples, usage environment, etc.) and your requirements (quantity, delivery date, etc.).We will recommend product solutions and quotations to meet your requirements.

Contact Details:

TEL:18025468212 / 0755-26793059,

WeChat:18025468212

Q Q:2311257469

E-mail:HaoRuiGongYe@126.com

Thank you for your browsing, we are confident that we can fulfill your product requirements well and look forward to be your reliable partner!

Browse more products, please click

【Wechat】

【Wechat】